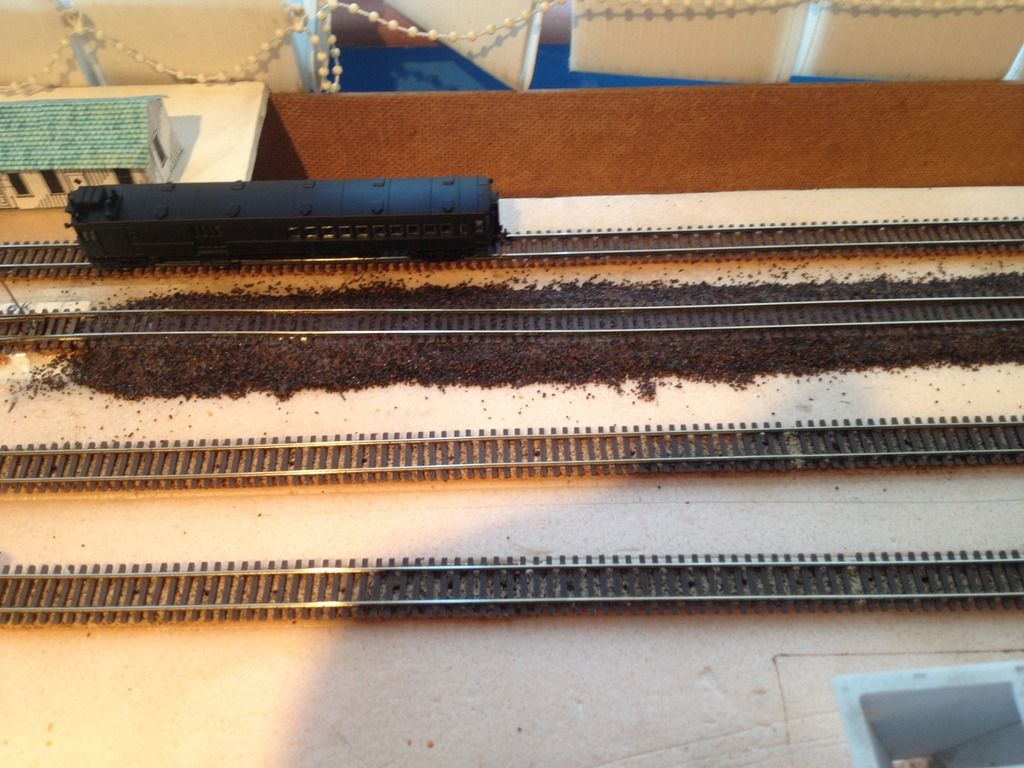

Track work:

After getting the turnouts fixed in place, the time came to

more permanently fix he track. Since this area of the layout is going to

portray a weed-grown locale, I thought to deviate from my normal approach of

scenery then ballast, effectively killing two birds with one stone by

ballasting this track.

The dark ballast was left over from a long time ago, and I

have slowly been using it up wherever I want to have a variety, especially

since the “normal” color will be light grey. Hopefully I have enough left to

finish the branch line terminal and tracks, or I will have to find a

replacement.

I also filled under the floating section from the previous

post; it went a lot easier than I expected, and can hopefully get everything to

a point where I can start the scenic effects, and ballast around the turnouts.

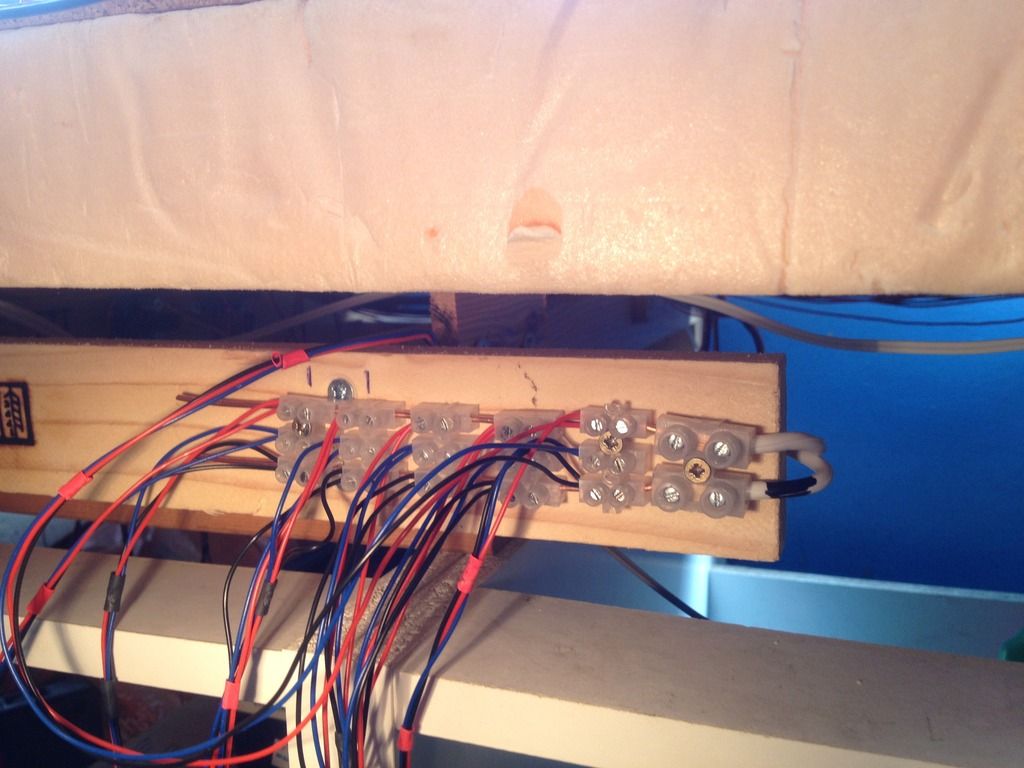

Wiring:

What good are remotely powered turnouts without the means to

work them? As I am powering all of them from a separate transformer, I had to

run a bus wire around the layout from the outlets to the control switches,

which will be mounted on the fascia.

Power Bus Approach:

I came up with the idea of using household mains cable as a

power bus to avoid running dozens of jumpers. It definitely made life easier on

the loft layout, so I thought I would give it a try where it presented itself.

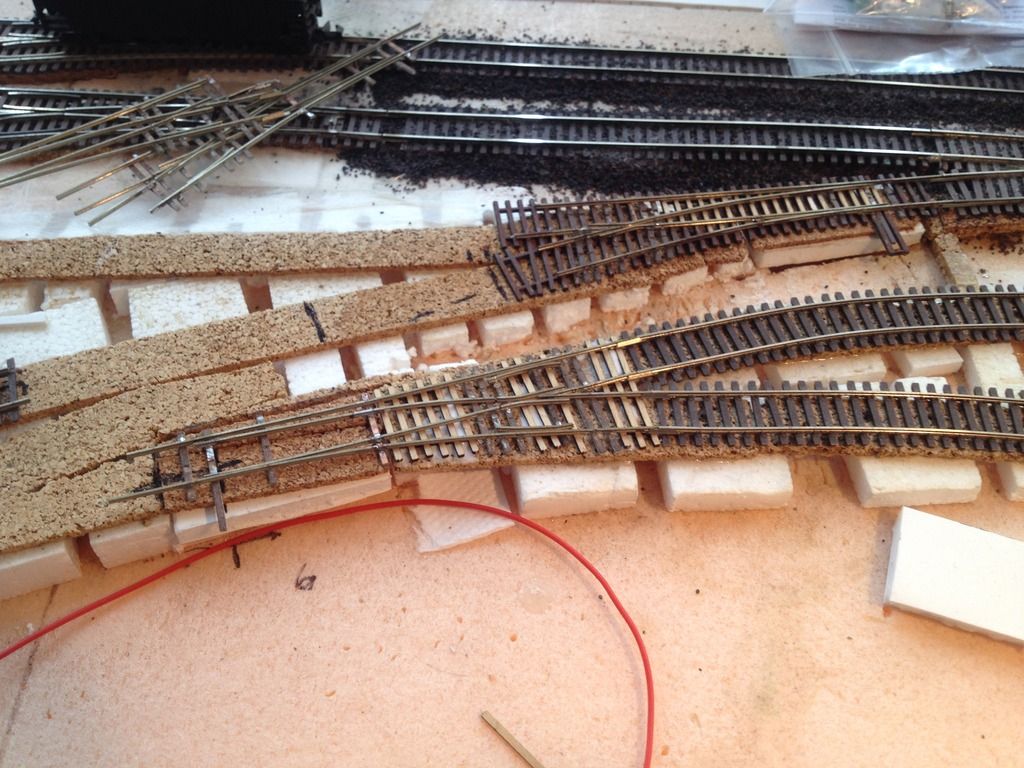

Planning the code 40 turnout installations

I actually built these years ago, but have delayed

installing them due to issues over control. The basic problem was that I could

not find a readily available supply of components that did the job in a

cost-effective manner, which I was happy with. Having decided that servo motors

fit the bill, I can now get on with it.

Here you can get a better look at the placement of the

future turnouts from the tie strip placement. I’ve also shown the servo

mounting board with tie strip attached.

Change to mounting practice

I had been installing the servo on its edge to save space in

the footprint, but oddly could not get proper throw in this location using that

method. As a possibility I tried turning the servo back on its side, and

problem solved. The throw wire is actually thicker than the stock wire

provided; I just could not be bothered to change it after I realise it did not

solve the problem.

This image shows the revised mounting method.