I managed to find some local power transformers that make

the servos run really well, so after a bit of experimentation (fun!) with that,

I dove back into the finishing up the branch line junction.

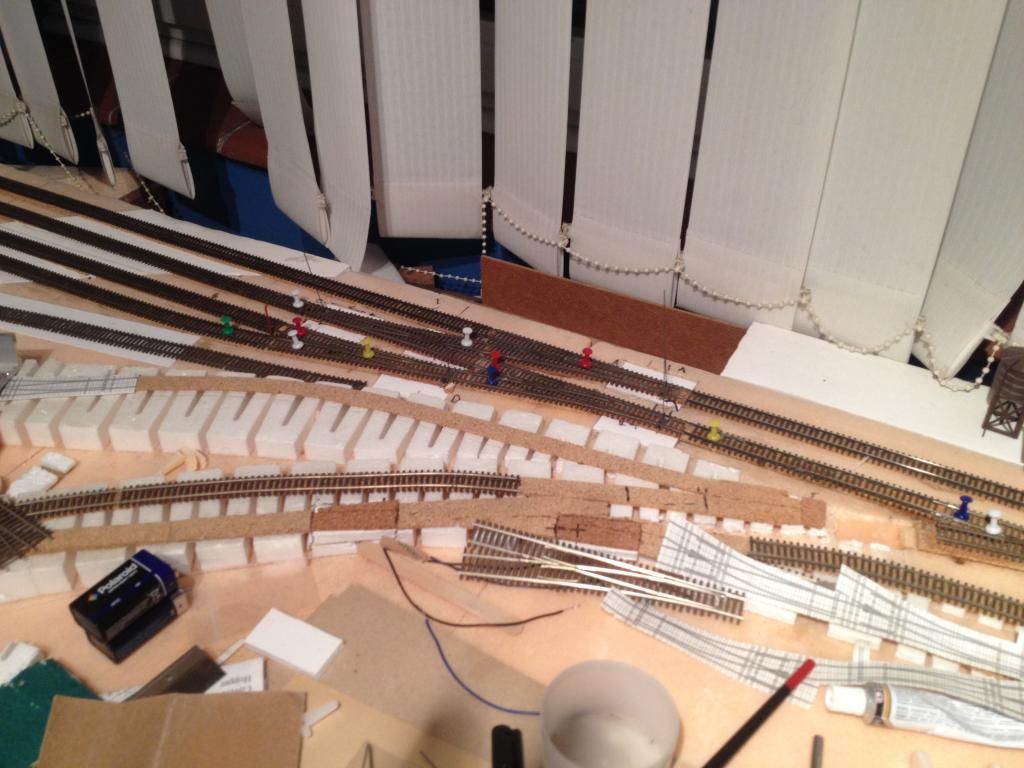

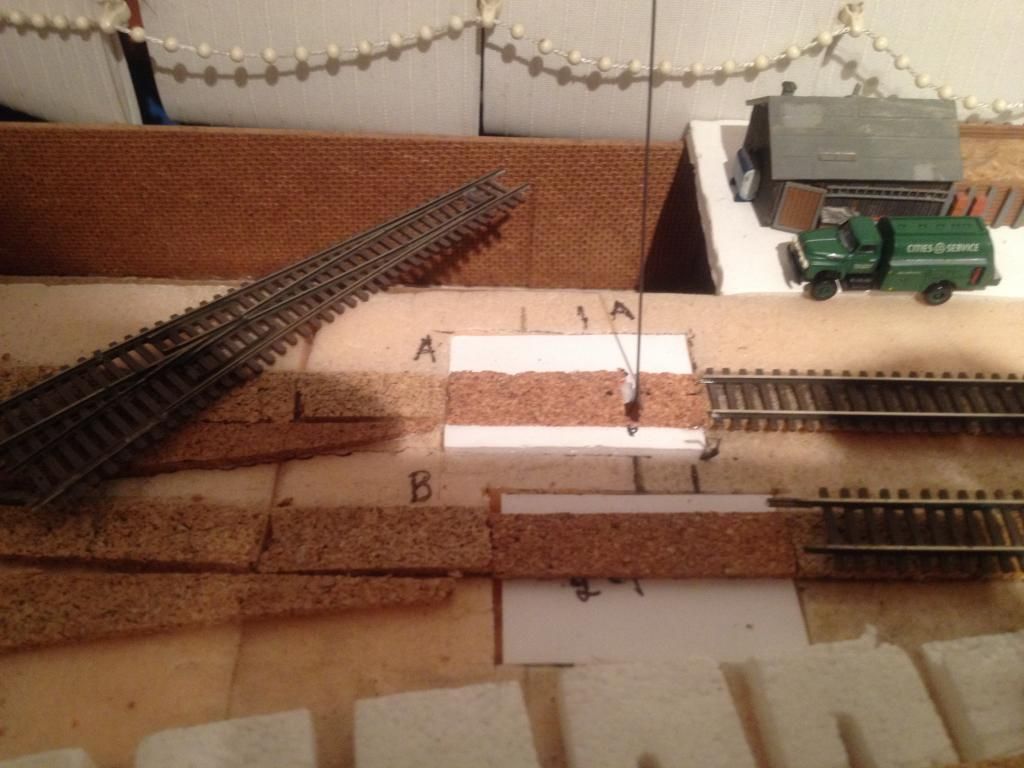

I kind of got to this state before Thanksgiving, which took

a slight bit of time out of my free-time pool. Getting decorations up for

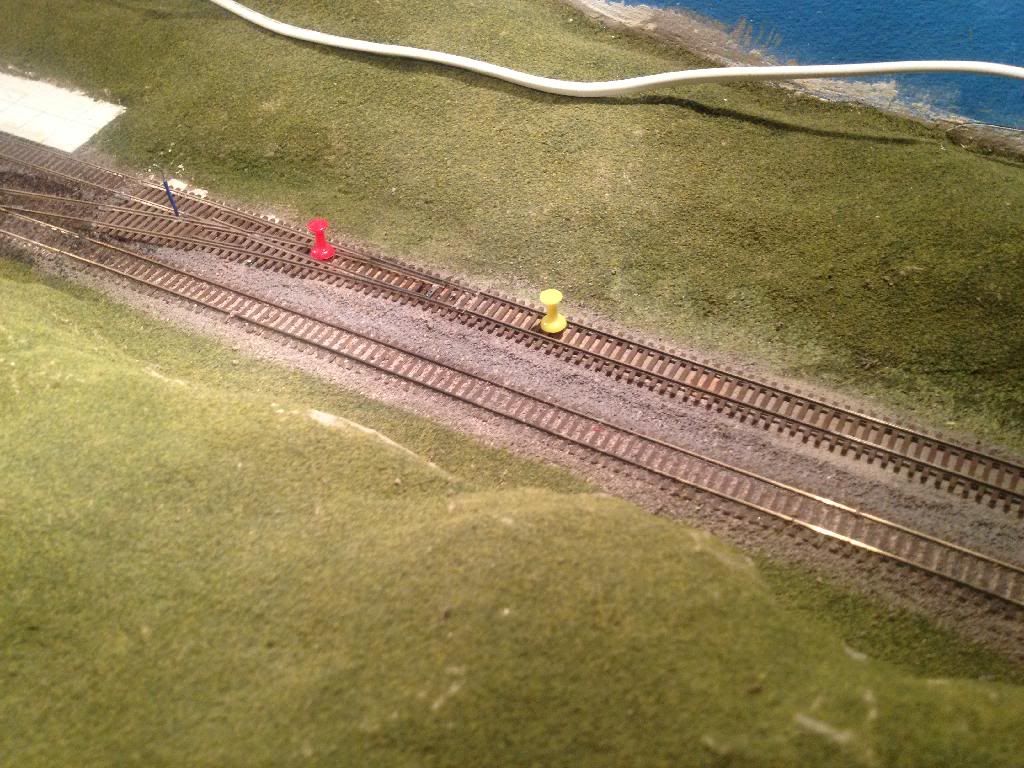

Christmas, etc., well, you know how it is. This was the last "shot"

of the work in progress:

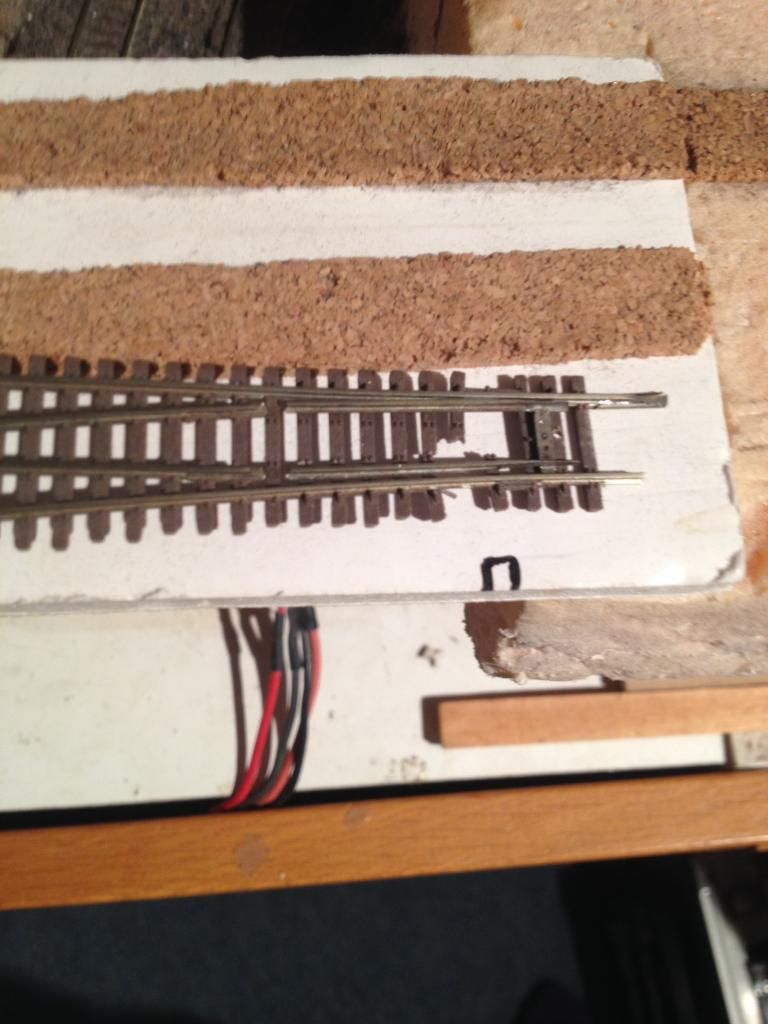

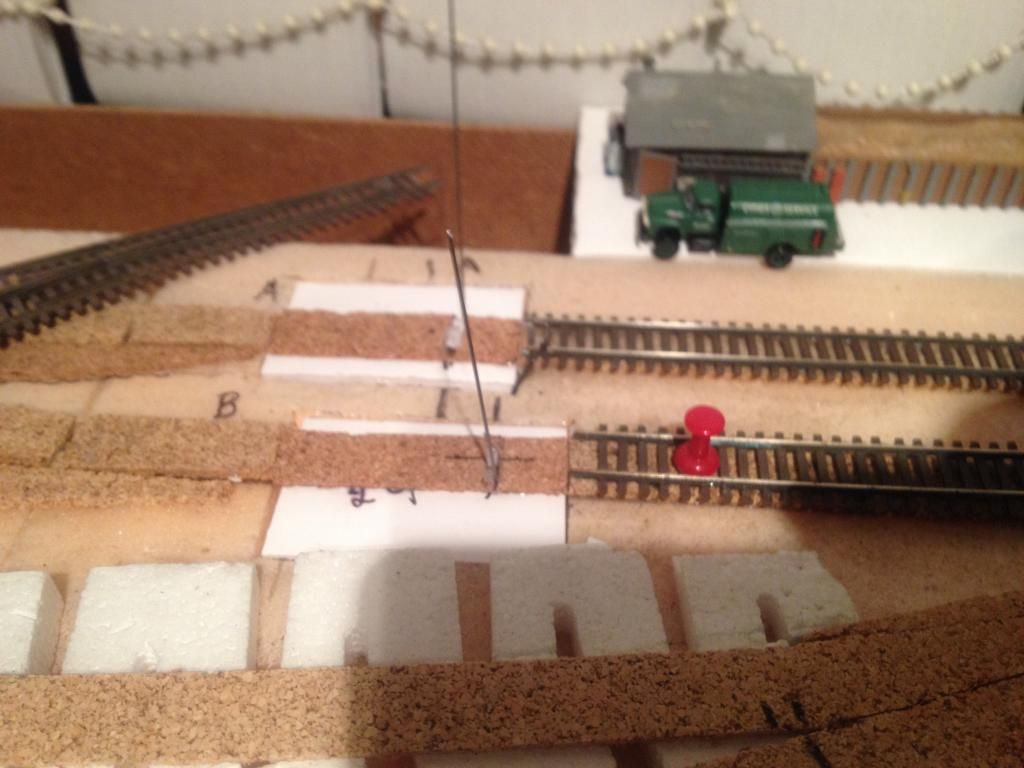

All well and good, right? Not quite. One of the turnouts was

not behaving properly. And if it was being a pain now, it could only get worse,

right? So I decided to pull it out and attempt to fix it, when this happened:

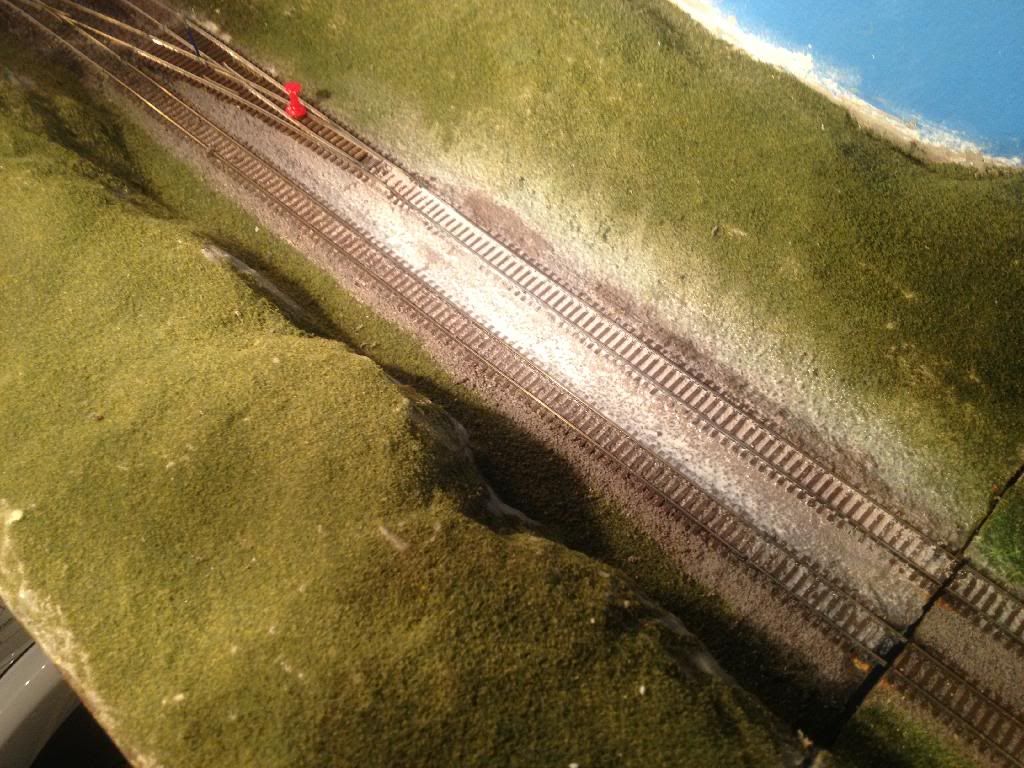

Well, I can salvage the rail, frog, and guardrails. The project

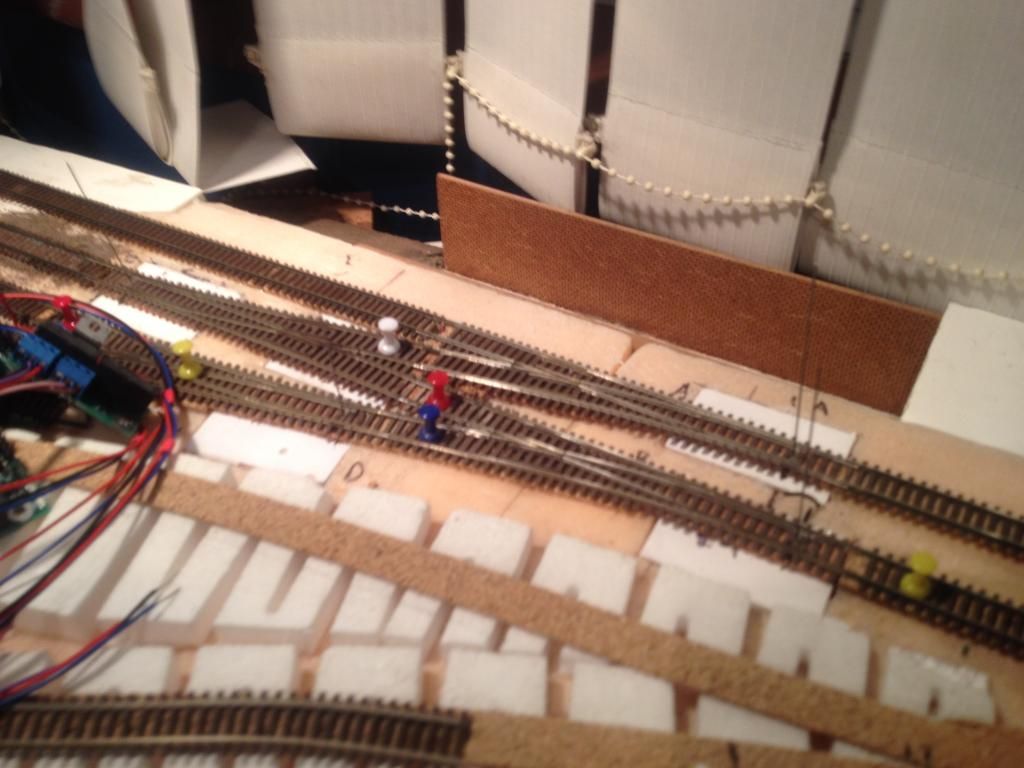

wrapped up in this state, kind of a regression:

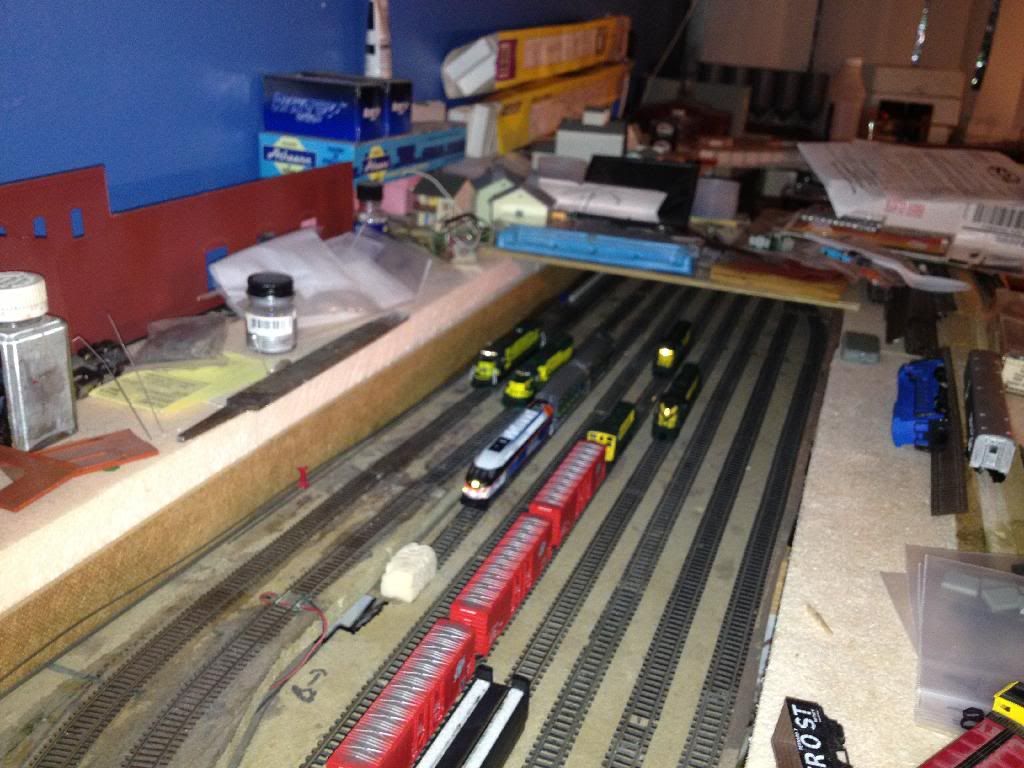

Until today! I got home a bit earlier than usual from work,

no major crisis causing me to connect back in from the house, so I decided to

get the replacement turnout in place. So I did; back to where I was a few weeks

ago!

It doesn't feel so much like lost time, since it does seem

to work better, so I'll stick to that. I also decided to start on the foam

"shaping" that would be needed prior to scenery.

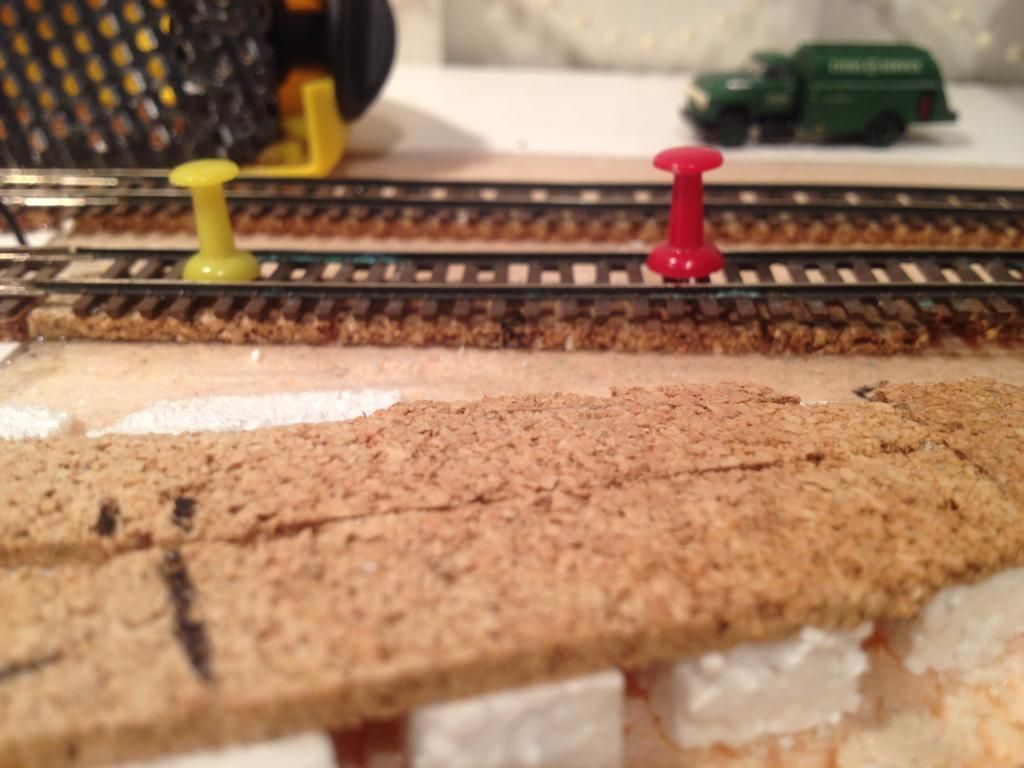

I used the Woodland Scenics risers to elevate some of the

track, but it is just too wide for an N scale industrial area, so I sloped the

edge of one section down to the base:

The sanding tool was making kind of a mess of the cork as

well as the foam, so I only used it to keep a smooth line along the rough

shape. I then used the course sandpaper to finish off the shape. Later, once I

have hooked up all of the feeder wires and powered up the turnout motors one

more time, I cover this with paper, and paint that over with PVA prior to

applying the scenery.

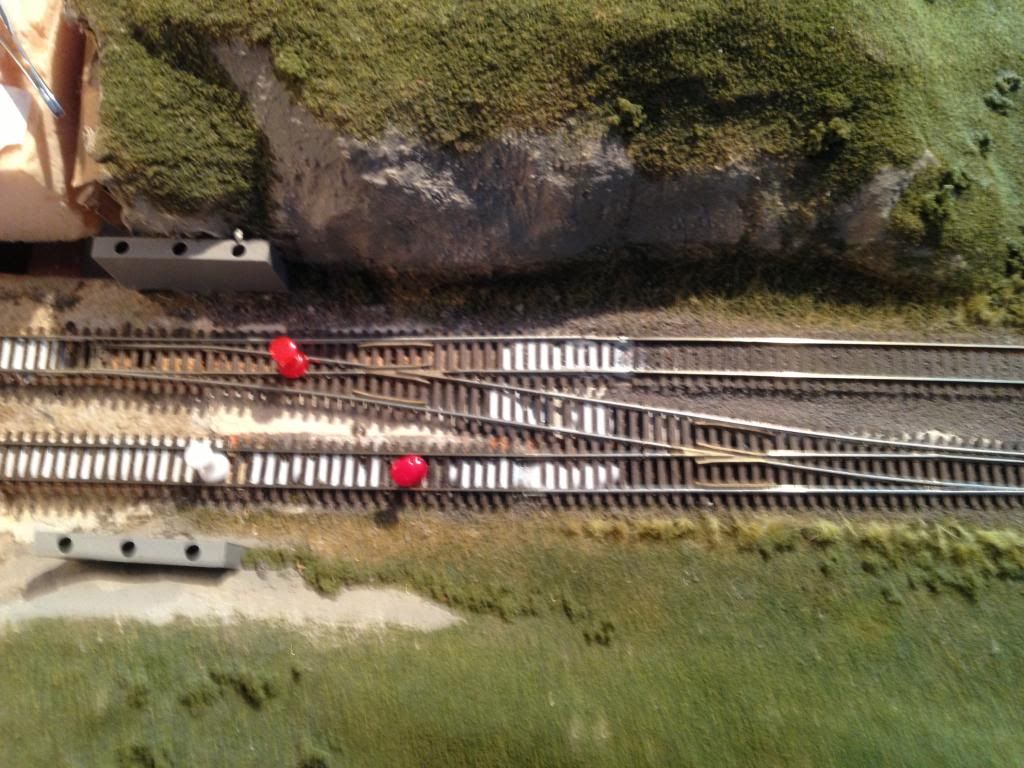

One more challenge to face: the smoothing of one of the

"transitions" in height. Gluing the track to the cork left a rather extreme

elevation change, so I may resort to using ballast to fill in under this

stretch to support it, in a more even grade change:

The track seems to find its own level, so I may trust in its

choice on this one occasion, and let it be.

Off to do the wiring, both track and turnout motor SPDT

toggles, so won't be much more to show tonight. Hopefully this weekend I'll get

trains running on this again, which has

not happened very well in quite a while...