It has been a long time (again) since I updated progress.

But I have been doing a lot of fun things, though not all train related...

I posted in a few places about experiments with servo

motors. So far things are looking pretty good. The Iowa Scaled Engineering

products offer different control boards, with two types of relay contacts, to

control point & frog polarity, or external contacts. Since I wanted to use

the contacts to drive signaling on the main tracks, the MRServo-3 product seems

a good match for the mainline and branch line tracks.

So I started installing them:

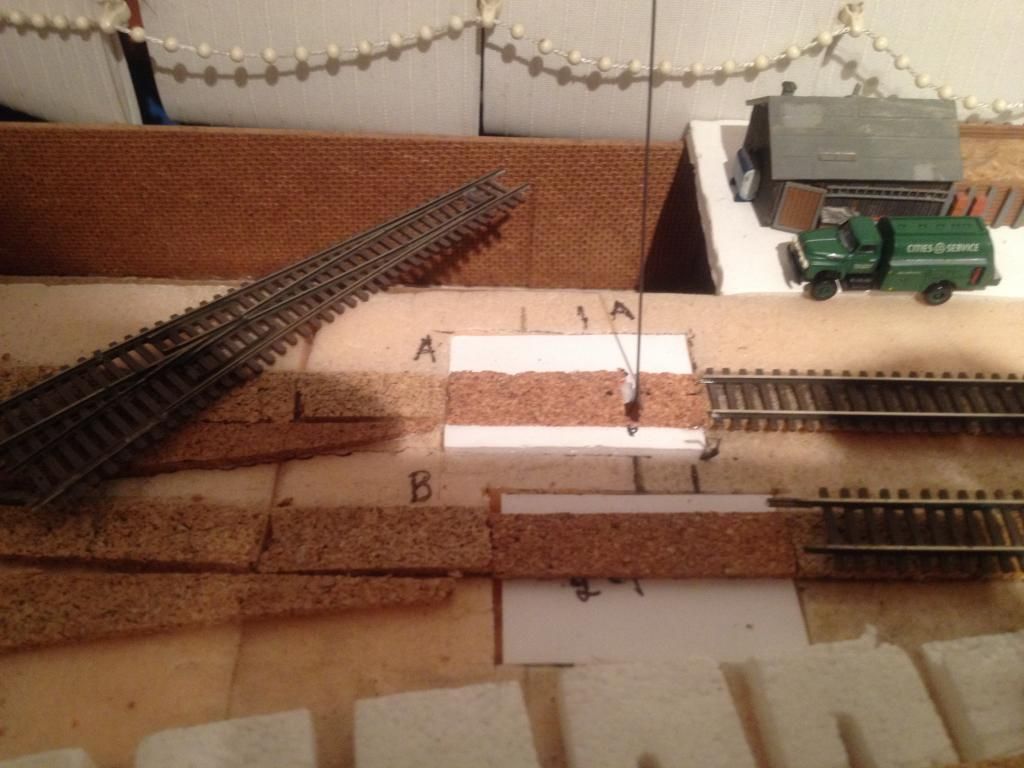

The rectangle of foam core in front of the station mock up

will be the first servo install. I will use a different controller board

(MRServo-2) on the left-hand installation (where the hole is) with basic power

routing and gaps in the rails for the hand laid turnouts.

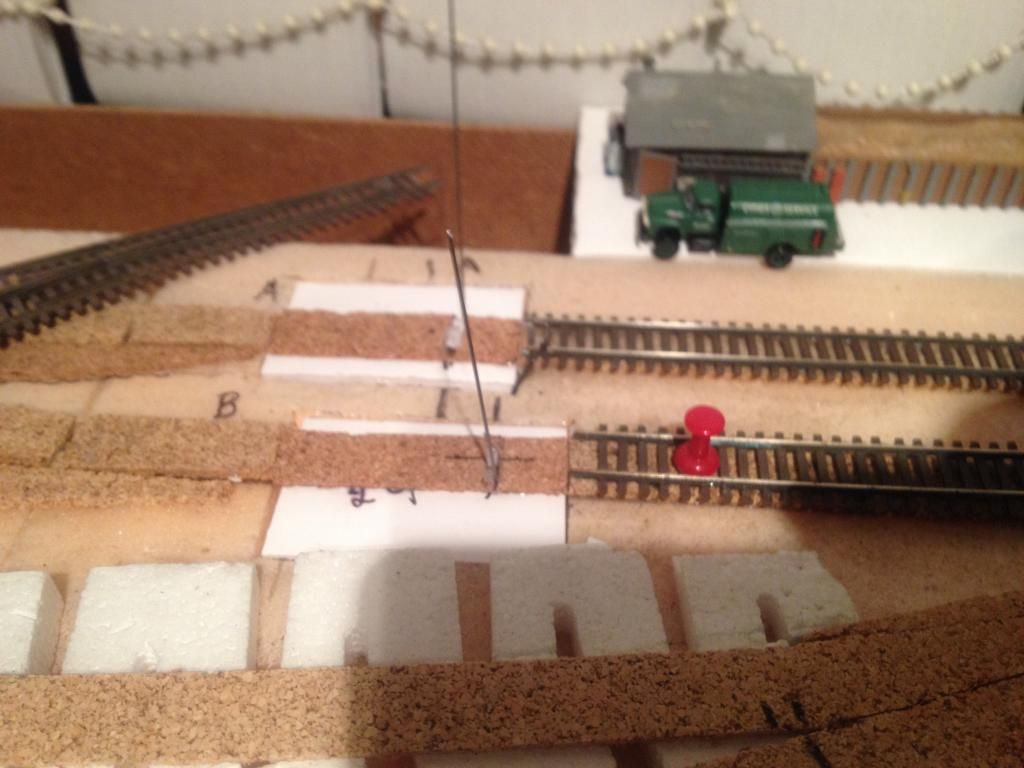

These four turnouts form crossover and two sidings. One of

the mounting holes is in the wrong spot, and has since been moved.

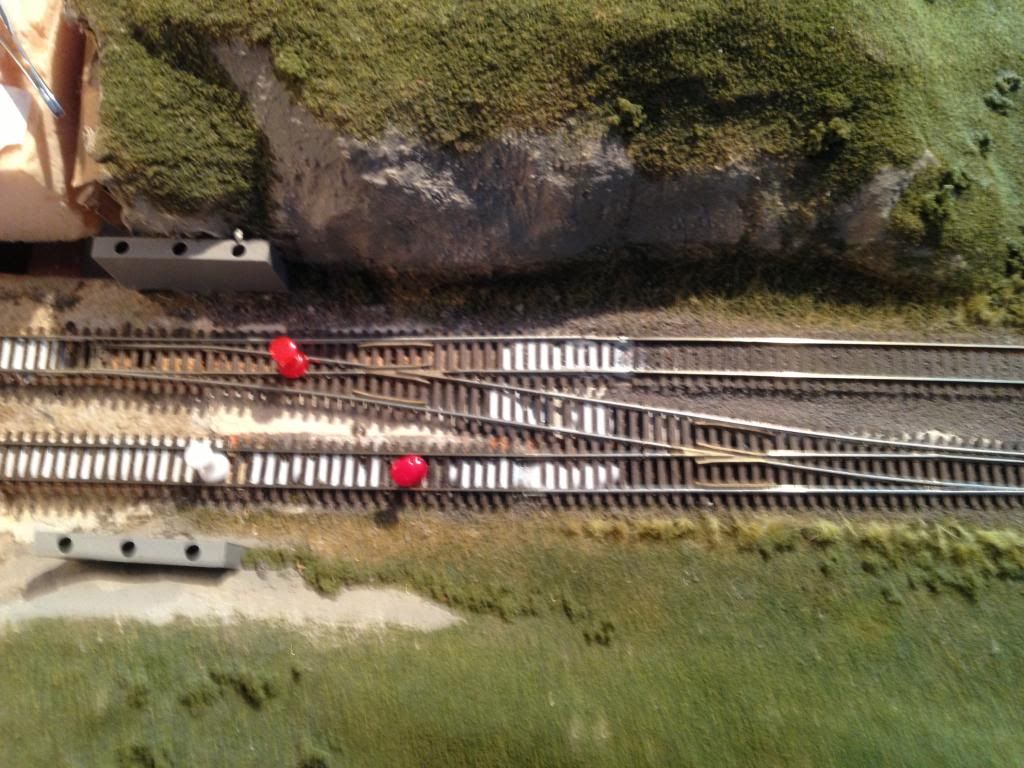

The second installation was much easier than the first,

after applying lessons learned.

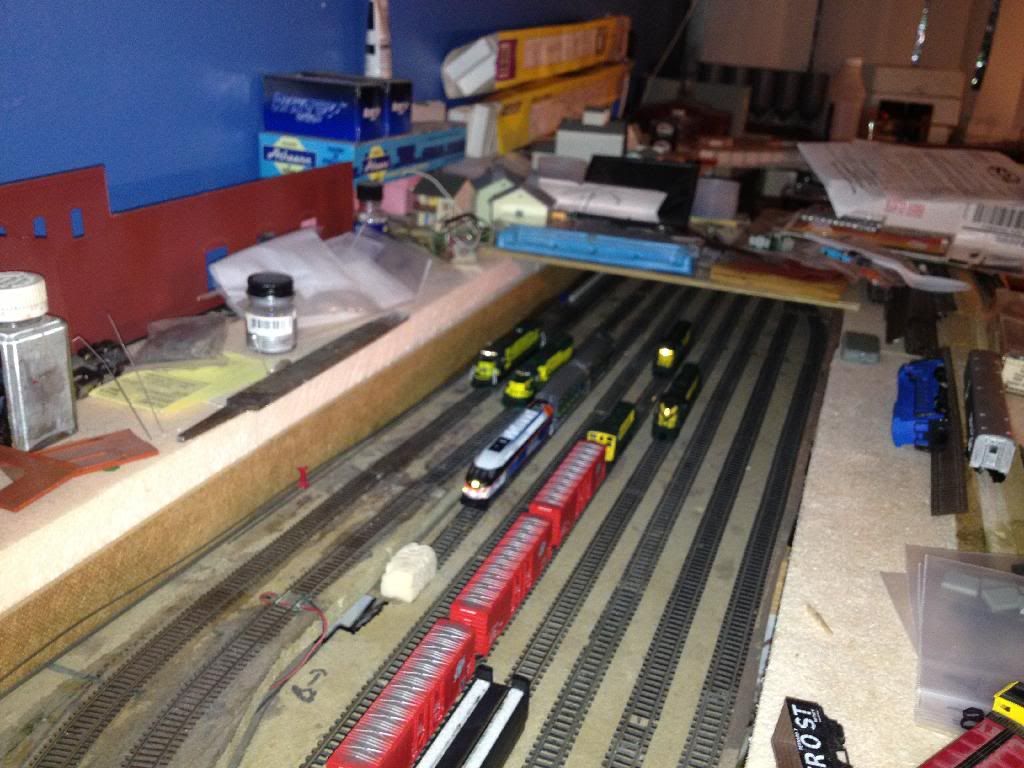

They are sprouting everywhere! Once I get the other two in,

I can look to replace and wire the track back up and test it with some trains.

Then one more major challenge to undertake!