Two major events occurred that have made a huge difference on the layout project, one visibly, and one operationally.

1. Visual Improvments - Bedford Valley grows!

I managed to acquire a failrly large haul of N scale structure and rolling stock kits through a friend on Ohio. I had these shipped to a relative's house in the states so I could sort through them to ship them more economically, and made several that were of no use to me available to other local modellers.

Included in this were several Magnuson Models resin kits, two of which will add some character and "back home" real estate to the now larger City of Bedford Valley

Bedford Valley 2.0 - The City Grows!

In addition, during recent months a number of very good quality N Scale city structures have released as well, allowing me to expand the footprint of the City of Bedford Valley. The townhouses will move to the left of the structures here, between them and the Downtown Deco kits that will transition the city image into industrial uses.

Expanded Bedford Valley

Expanded and reorganized following acquisitions, there will be more American buildings present, as well as a few taller structures to up the skyline a little.

The control panel installation has also meant changes in the city footprint in the foreground of the layout:

Future Site of Red's Bar

The fascia allowed me to widen the city area enough to place a small structure on this corner; I had been agonizing over where to place this small structure for weeks, and once it is lighted, will be in a perfect place to show it off.

2. Operational Developments:

While attending the International N Gauge show this year (and meeting up with fellow N scaler Andy (a.k.a. Texhorse)) I discovered a small vendor offering some some very interesting, practically plug and play control boards for turnout control...

megapointscontrollers.com/

Dave that runs the operation with his wife Shiela, and gave some very clear and helpful demonstrations of their product line, which can control up to 192 turnouts through linked boards, and 192 programmed routes using a panel processor.

Accessory boards can be chained to the system to power frogs through relays, or provide auxiliary controlled power based on the throw.

How far I will go with this option is not clear, but at £60 (approximately $75) to control 12 turnouts, and an additional £72 (approximately $90) if I want to add automated power routing (which I am also testing via a double or triple pole toggle switch to drive the turnouts). The system is modular, so I can easily "just" power the servos at present, and add the relay cards if I wish to add route control later, without having to do a major electrical engineering project.

At the current exchange rate it means I can save a few dollars on twelve installations, and just over the cost of the twelve single control boards I can add the relays and have a foundation for route control. The major benefits are a local supply, and the ability to build up the features in a modular manner, rather than commit to everything up front.

Where might this lead?

Single boards are great for the mainline away from the control panel on the larger layout. The MegaPoints system lends itself to the more congested yard areas and smaller layout. I'll have to doodle with routing to determine how far I might want it to go, but certainly lends itself to freight and passenger yard operation, to pick from up to 192 routes through a station and freight yard for example.

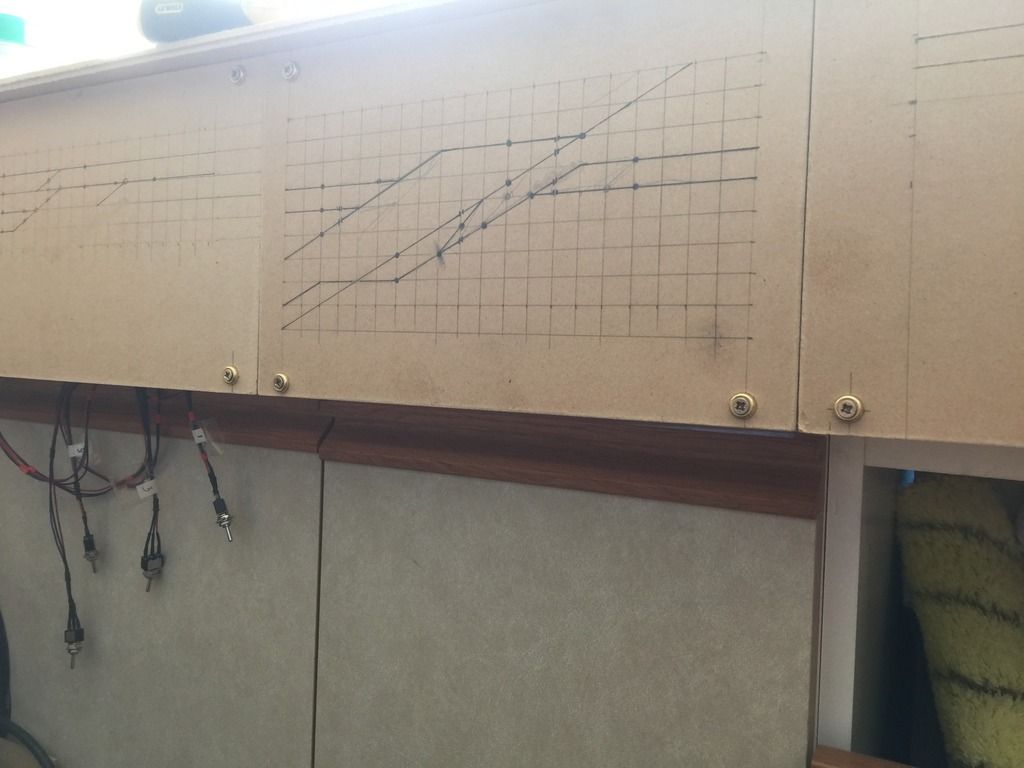

It has meant track gang has been called back to work, to facilitate mounting of turnouts and motors in the industrial area, after a rather long hiatus.

Turnout Repair Time

Some of the soldered joints were not very strong, and resisted resoldering them,. I ended up replacing the frog and all ties past connected to it and beyond.

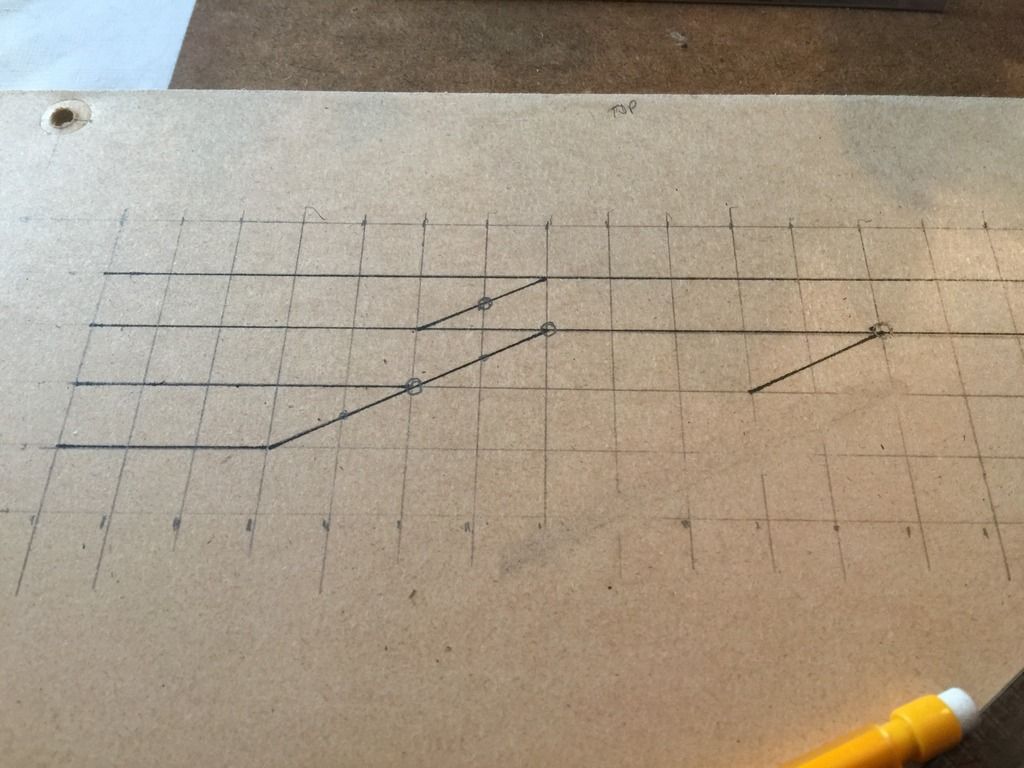

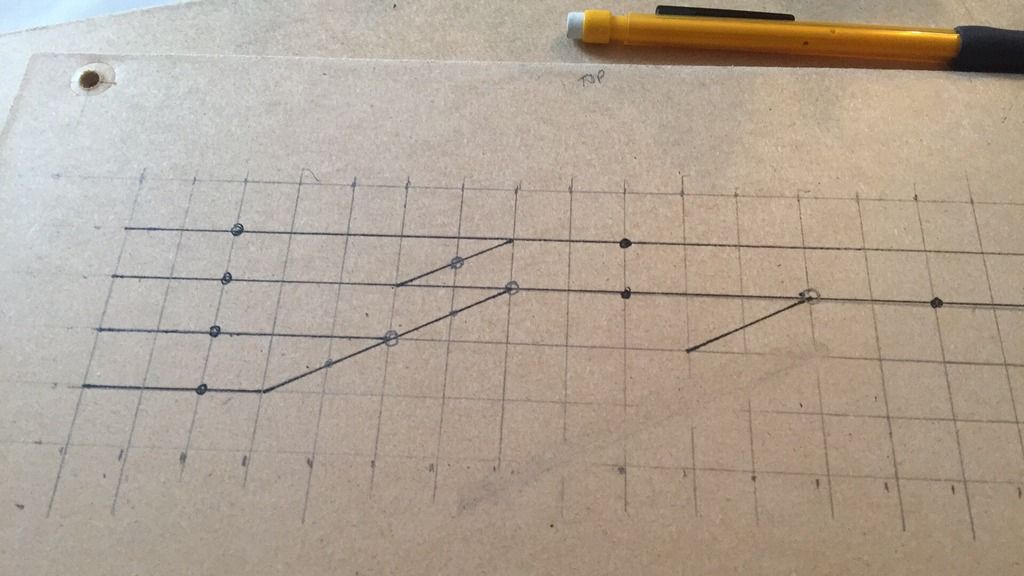

Hole Cut for Turnout Motor

New servos, and new controller boards, mean I can make progress on this neglected projected again, and hopefully get trains running through here under their own power soon...

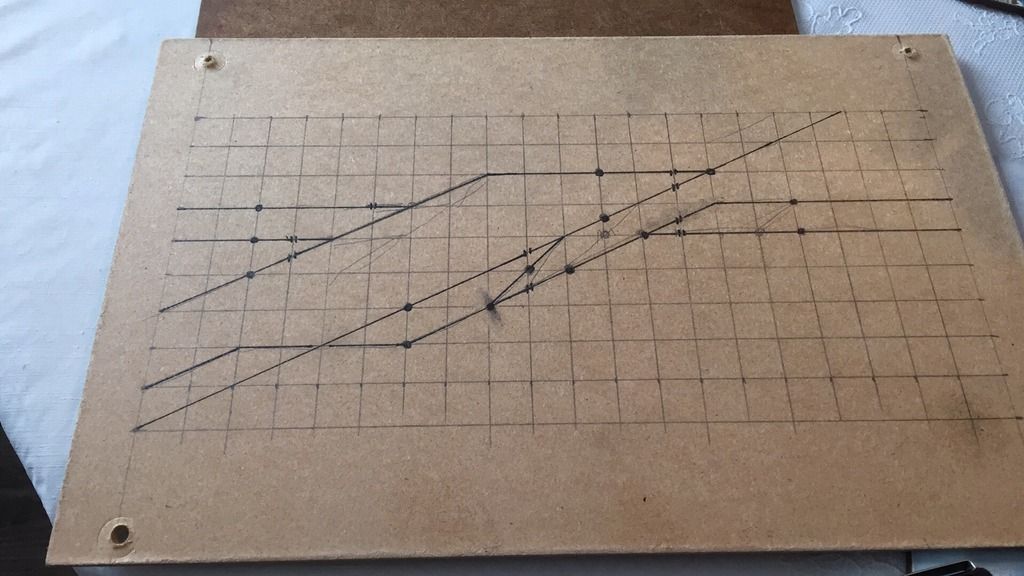

More Turnout Motor Mounting

These turnouts have not even been built yet, and this will be the next extension of completed track, the old power plant sidings.

I'll continue to plug away at it, and add another update once a few of the works in progress are completed...