This turnout has been a pain in my neck for some time; some

days seems like everything is happy, then on tiger days nothing seems to make a

full circuit without hitting dead track.

Turns out my choice of location for a frog power feeder was

all wrong (and it was a poor job of soldering!). Just past this connection,

between it and the frog, is a manufacturer supplied owner gap. So no power was

getting anywhere near the frog. Since I bought the turnouts second hand, I did

not gave any documents explaining things.

Here's the offending part:

While preparing to replace the turnout after a soldering

mishap (to bridge the gaps) I discovered a metal fitting on the bottom,

presumably to hold the frog assembly in place. I managed to attach a feeder

wire to it, and job done. Solid, working electrical connection completely out

of sight!

Armed with new knowledge I proceeded to the next instance of

trouble; in this case, bad advice from the Internet, about cutting gaps. As I

have learned, the gap is already there, so they, and the insulated rail joiners

on the frog rails, are not necessary.

Also, part of the plan is to swap the Cicuitron Tortoise

motors for servos, making storage a lot easier as the vertical footprint is

significantly reduced.

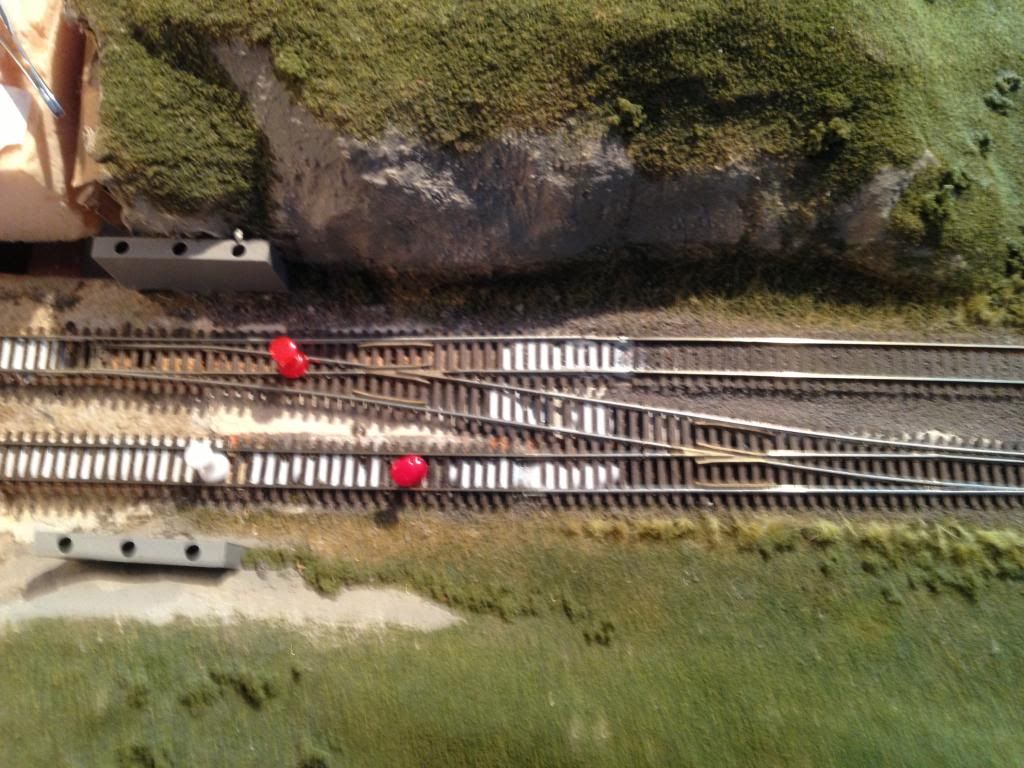

So I set my sights on replacing this entire crossover:

Removing them was the easy part; removing the track and

scenery while trying to preserve the scenic features away from the track was a

pain.

Getting back to a connected loop:

I replaced all of the removed trackage, and secured it in

place with PVA well away from the moving parts. After everything dried I

installed three new sets of feeder wires, one at each of the two point ends of

the turnouts, and the third on the main rout of the front turnout. There are

four blocks on the lift out, but all are connected with other track off the

lift out. It's logical, and saves me running extra wiring and the bus for

power. Four sets of connections for track power, and one for the turnout motors

is complicated enough. Besides, the next big project is motorising the crossing

gates...

No comments:

Post a Comment